Post-Tension Courts

Create a Slice of Paradise for You and Your Family!

Why post - tension? Conventional concrete has the tendency to settle, crack or heave. Those conditions most often end up occurring with the weather changes or drought and wet cycles. The results are an unsafe court surface and tripping hazards. No one wants a court with a tripping hazard. Post Tension prevents settling and tripping hazards from happening and greatly extends the life cycle of your court.

How are our post tension courts built?

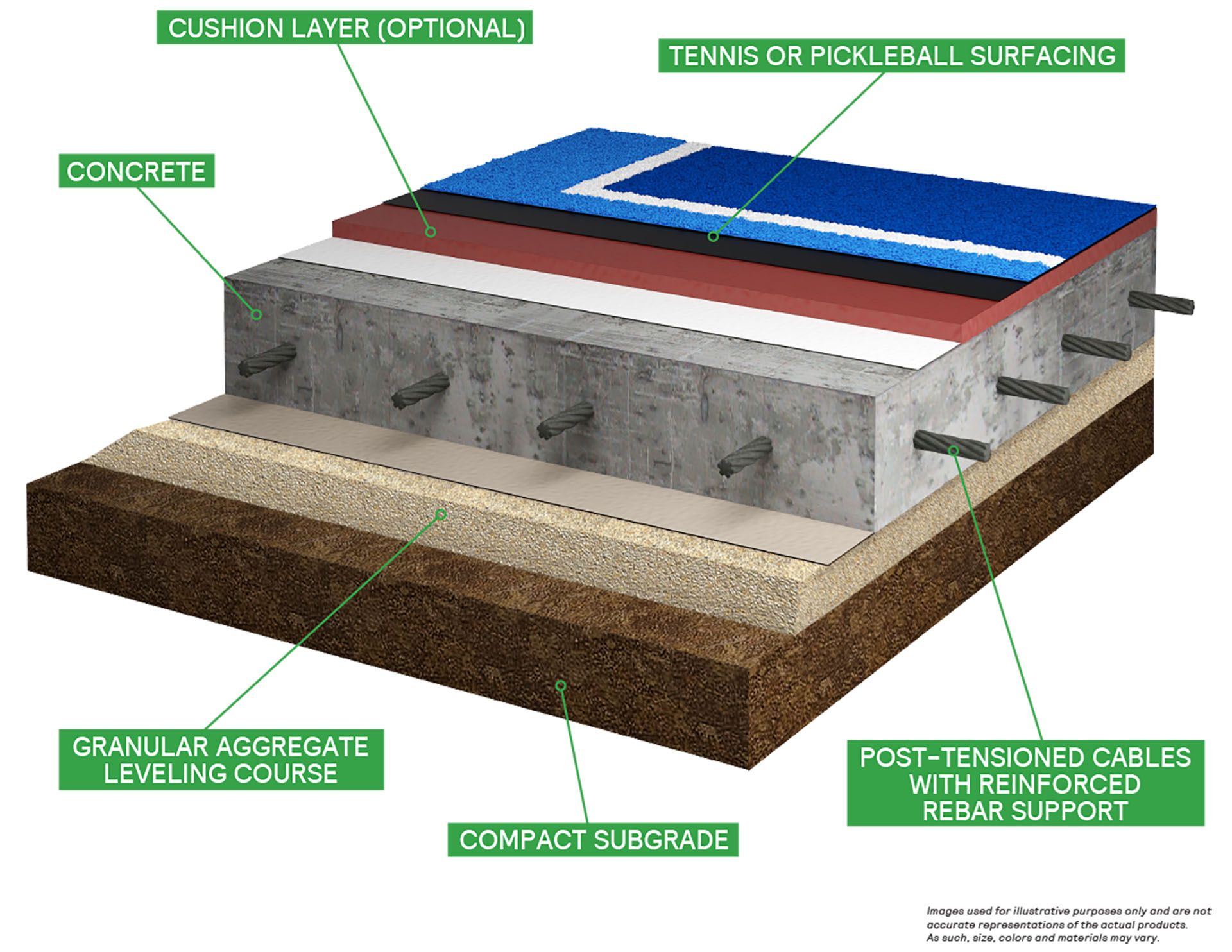

We compact and prepare the subgrade ready to receive a rock drainage layer under the new court surface then forms are set for a 5” slab with a 1’x1’ thickened edge. We place a vapor barrier on the rock drainage layer then place the post-tension tendons on a grid throughout the court. These tendons are sandwiched with rebar on the outer thickened edge of the court footprint. After placement of concrete the next day we stress these cables to approximately 9,000LBS. After the concrete has surpassed 2,200psi approximately 7 days later we then perform a final stressing of the cables to 33,000LBS. This makes the posttension court slab as one and, if and when any of conventional concrete issues (Settle, Crack or Heave) attempt to occur the posttension reinforcement prevents that from happening.

WITH POST-TENSIONED CONCRETE, YOU CAN:

- Span unstable soil

- Increase resistance to settling and heaving

- Eliminate cold joints around net and fence posts

- Enjoy better uniformity of play

- Provide a consistent slope for drainage

- Create a stable, aesthetic concrete edge

- Eliminate potential liability due to structural cracking

- Build on top of existing courts saving demolition costs

REMAINS DURABLE IN POOR SOIL CONDITIONS

If expansive soil starts to move, the concrete slab actually floats and performs independently due to constant cable compression.

IMPROVES DRAINAGE

Reduces water holding areas and provides consistent slope allowing for a highly competitive surface.

RESISTS CRACKING

The post-tensioned slab is kept in a constant state of compression so it remains durable and stable during weather fluctuations and extreme conditions

MAKES USE OF EXISTING SITES

Reduces removal costs and potential unforeseen subgrade conditions.

Strong from start to finish

1. Laser Grading

After the rough grade is established, the fine grade is achieved using a laser-controlled machine to provide a true plane.

2. Beam & Cables

An enlarged perimeter beam is excavated to anchor the stressing cables. Engineered cable spacing is determined by tendon length and soil conditions.

3. Concrete Placement

Concrete is placed using laser-controlled equipment or A-frame screed to achieve the precise slope and planarity.

4. Concrete Finishing

Equipment designed for finishing large slabs ensures uniform planarity and texture.

5. Fence Posts

Fence posts are wet set into the perimeter grade beam eliminating cold joints.

6. Tendon Stressing

Once the concrete has reached the specified compressive strength, the cables are then tensioned.

7. Fencing

Fence options include vinyl clad chain-link, galvanized chain-link or customized fences. Fencing can also be engineered for wind screens.

8. Surfacing

The final surface choice can range from one of our Renner Cushion systems or Renner Classic color coating systems meeting ITF Pace Ratings.

All Rights Reserved | MULTISPORTS | Powered by Aletheia Digital | Privacy Policy